Starting a career in civil engineering is exciting, but going for your first job interview can feel a little scary. As a fresher, you may not have much site experience, but interviewers will still expect you to know the basics of your subject. They will ask questions to check how well you understand civil engineering concepts and how ready you are to work on real projects.

This blog post will help you prepare for those interviews. It includes 101 common questions that are often asked during civil engineering interviews for freshers. These questions cover all the important areas like concrete, structures, soil, surveying, construction work, and even some basic project management and environmental topics.

The questions are grouped by topic so you can study them easily. We’ve also included a few simple tips to help you give better answers and feel more confident during your interview.

Whether you are preparing for a campus interview or applying to your first job in a company, this guide is made to support you every step of the way.

Let’s get started with the most important civil engineering questions every fresher should know!

Basic Civil Engineering Concepts

What is civil engineering?

1. What is civil engineering?

Civil engineering is a branch of engineering that focuses on the design, construction, and maintenance of infrastructure such as roads, bridges, buildings, dams, and water systems. Civil engineers work to ensure that these structures are safe, functional, and durable. They apply principles from various fields like physics, mathematics, and material science to solve real-world problems. Civil engineering is crucial for shaping cities, improving transportation, and providing basic utilities like water and electricity. It’s a field that combines creativity with technical knowledge to build and improve our living environment.

2. What are the major branches of civil engineering?

Civil engineering has several branches, each focusing on different aspects of construction and infrastructure. The major branches are:

- Structural Engineering: Deals with the design and construction of buildings, bridges, and other structures.

- Geotechnical Engineering: Focuses on soil and rock behavior, foundation design, and ground stability.

- Transportation Engineering: Involves the design and maintenance of transportation systems like roads, highways, and railways.

- Environmental Engineering: Works on water treatment, waste management, and pollution control.

- Construction Engineering: Focuses on managing construction projects from start to finish.

These branches work together to improve and maintain the built environment.

3. Difference between RCC and PCC?

RCC (Reinforced Cement Concrete) and PCC (Plain Cement Concrete) are both types of concrete used in construction, but they differ in strength and usage.

- RCC is concrete that includes steel reinforcement bars (rebars), which enhance its tensile strength. It is used in structures that need to withstand bending, like beams, columns, and slabs.

- PCC is just a mixture of cement, sand, and aggregates with no reinforcement. It is used for foundations and floors where there is no need for added strength to resist bending forces.

RCC is stronger and more durable than PCC.

4. What is the unit weight of concrete?

The unit weight of concrete is the weight per unit volume, and it typically ranges between 2200 to 2500 kg/m³ (kilograms per cubic meter). The exact weight depends on the type of materials used and their proportions in the mix. For example, normal concrete made with standard aggregates has a unit weight of about 2400 kg/m³. This measurement is important for structural calculations, as the weight of concrete affects how much load it can carry and how it behaves under different conditions. Higher unit weight concrete is often used for high-strength applications.

5. What is a cantilever beam?

A cantilever beam is a beam that is fixed at one end and free at the other. This type of beam is commonly used in bridges, balconies, and overhanging structures. The fixed end resists bending and supports the entire beam, while the free end can extend without additional support. Cantilever beams are designed to withstand bending forces by using strong materials like reinforced concrete or steel. When weight is applied to the free end, the fixed end resists the force, keeping the structure stable. The beam needs careful design to avoid excessive deflection or failure.

6. Define moment of inertia and its significance.

Moment of inertia is a property of a body that defines its resistance to rotational motion about an axis. It depends on the shape of the object and how its mass is distributed. In civil engineering, it is used to calculate the bending of beams and structural elements under loads. A higher moment of inertia means the structure is stiffer and less likely to bend. It plays a key role in designing safe and efficient structures. For example, beams with a high moment of inertia are used in bridges to prevent excessive bending and ensure stability.

7. What is a footing and what are its types?

A footing is a part of the foundation that transfers the load of a building to the ground. It is designed to spread the weight over a larger area to prevent settlement or tilting of the structure. There are several types of footings:

- Slab Type Footing: A simple flat slab used in small buildings.

- Strap Footing: Used when the loads are unevenly distributed.

- Isolated Footing: Used for individual columns, commonly seen in residential buildings.

- Raft Footing: A large slab that covers the entire area of a structure, used for weak soil conditions.

Footings are essential for stability and prevent foundation failure.

8. What is compaction?

Compaction is the process of increasing the density of soil by reducing air gaps between particles. It’s done by applying mechanical force, such as using rollers or tampers. In civil engineering, compaction is crucial for preparing the ground before building foundations, roads, or pavements. Well-compacted soil has better load-bearing capacity and is less prone to settlement. It also improves the stability and strength of structures by reducing water infiltration. The level of compaction is tested using various methods, like the Standard Proctor Test, to ensure the soil meets the required standards for construction.

9. What is the difference between load-bearing and framed structure?

A load-bearing structure is a building in which the walls themselves carry the weight of the roof and floors. In this system, the walls are thick and made from materials like brick or stone to support the load. The weight is distributed across the walls.

In a framed structure, the weight is carried by the framework, typically made of steel or reinforced concrete. The walls are non-load-bearing and mainly serve as partitions or enclosures. Framed structures are more flexible and can have larger windows and open spaces compared to load-bearing structures, which are limited by wall thickness.

10. What is the modulus of elasticity of steel?

The modulus of elasticity (also known as Young’s Modulus) of steel is a measure of how much it will stretch or compress under an applied force. It is a constant value and typically ranges from 200 GPa (gigapascals) to 210 GPa depending on the type of steel. This property is important for designing structural elements like beams and columns, as it helps engineers calculate the amount of deformation the material will undergo under load. Steel, with its high modulus of elasticity, resists deformation well, making it ideal for use in construction where strength and stiffness are required.

👉 Tip: For fundamental questions, always answer with basic definitions and real-world examples.

Concrete Technology

11. What are the ingredients of concrete?

Concrete is made using four main ingredients: cement, sand (fine aggregate), gravel or crushed stone (coarse aggregate), and water. Sometimes, admixtures are also added to improve certain properties. Cement acts as the binder that holds everything together. Sand and gravel provide strength and volume, while water helps start the chemical reaction called hydration, which hardens the mix. The correct mix of these materials is important to get strong, durable concrete. If the proportions are wrong, the concrete may become weak, crack, or not last long.

12. What is the water-cement ratio? Why is it important?

The water-cement ratio is the amount of water used compared to the amount of cement in a concrete mix. It is written as a ratio like 0.5 (which means 0.5 kg of water for every 1 kg of cement). This ratio is very important because it affects the strength and durability of the concrete. If too much water is used, the concrete becomes weak and cracks easily. If too little water is used, the mix becomes too dry and hard to work with. A good water-cement ratio gives strong, workable, and long-lasting concrete.

13. What is curing? Why is it necessary?

Curing is the process of keeping freshly placed concrete moist and at the right temperature so it can harden properly and gain strength. When water is added to cement, a chemical reaction called hydration begins. This reaction must continue for several days to make the concrete strong. If concrete dries out too quickly, it will crack and lose strength. That’s why we keep it wet by spraying water, covering it with wet cloths, or using curing compounds. Curing is essential for durability, strength, and to prevent surface defects in the final structure.

14. What is the minimum curing period for RCC?

For Reinforced Cement Concrete (RCC), the minimum curing period is 7 days when using ordinary Portland cement. However, if the weather is hot or dry, curing should be continued for at least 10 days. As per IS 456:2000, curing should be done for 14 days if blended cement (like PPC or PSC) is used. Proper curing helps concrete gain its required strength and prevents cracks or shrinkage. It’s best to continue curing for a longer time if possible to ensure the concrete becomes durable and performs well over its life.

15. What is M20 grade concrete?

M20 grade concrete is a mix of concrete where “M” stands for mix and “20” is the characteristic strength of the concrete after 28 days of curing, measured in MPa (Megapascals). M20 concrete has a nominal mix ratio of 1:1.5:3, which means 1 part cement, 1.5 parts sand, and 3 parts coarse aggregate. It is commonly used in residential buildings, slabs, beams, and columns. M20 provides a good balance of strength and cost for general construction. For higher loads or bigger structures, higher grades like M25 or M30 may be used.

16. What do you understand by workability of concrete?

Workability is how easy it is to mix, place, compact, and finish concrete without segregation or losing strength. Good workability means the concrete can be spread and shaped easily without too much effort. It depends on several factors, like water content, mix proportions, aggregate size, and use of admixtures. If the mix is too dry, it becomes hard to place. If it’s too wet, it may be weak or segregate. The right workability helps workers pour and finish the concrete quickly and ensures the structure is strong and uniform.

17. What is slump test? What are standard values?

The slump test is a simple method to measure the workability (consistency) of fresh concrete. It uses a cone-shaped mold filled with concrete. After filling, the cone is lifted, and the concrete “slumps” or drops. The height difference is measured in millimeters (mm).

Standard slump values:

- Low (25–50 mm): Used in road construction (low workability)

- Medium (75–100 mm): Used in beams and slabs (normal workability)

- High (100–150 mm): Used in columns or congested reinforcement (high workability)

Too much slump may mean excess water, while no slump could mean the mix is too dry.

18. What causes segregation and bleeding in concrete?

Segregation happens when the heavy particles (like gravel) separate from the mix, while bleeding is when water rises to the surface. These problems occur due to:

- Too much water in the mix

- Poorly graded aggregates

- Over-vibration during compaction

- Dropping concrete from a height

Segregation causes weak spots, and bleeding can create cracks or reduce bonding with reinforcement. To prevent these, concrete should be mixed properly, placed carefully, and not overworked. Adding admixtures and using correct proportions also helps reduce segregation and bleeding in concrete.

19. What is admixture? Name a few common types.

An admixture is a material added to concrete during mixing to change its properties. Admixtures can improve workability, speed up or slow down setting, reduce water content, or make concrete stronger and more durable. They are used to suit different weather, site conditions, and structural needs.

Common types:

- Plasticizers: Improve flow without extra water

- Superplasticizers: Improve workability even more

- Accelerators: Speed up setting (useful in cold weather)

- Retarders: Slow down setting (useful in hot weather)

- Air-entraining agents: Improve resistance to freezing and thawing

Admixtures help make concrete more efficient and suitable for various situations.

20. How do temperature and weather affect concrete strength?

Temperature and weather have a big effect on how concrete sets and gains strength. In hot weather, water in concrete evaporates quickly, which can cause cracking, shrinkage, and lower strength. Rapid drying also stops proper curing. In cold weather, the chemical reaction that hardens concrete slows down. If it freezes before setting, the concrete can become weak and flaky.

To protect concrete:

- In hot weather: Use shade, add retarders, and cure properly.

- In cold weather: Use warm water, cover concrete, or use accelerators.

Proper temperature control helps concrete gain the strength it needs to last long.

👉 Tip: Use IS code references (like IS 456:2000) where applicable.

Soil Mechanics & Foundation Engineering

21. What is soil compaction and why is it important?

Soil compaction is the process of pressing soil particles tightly together by removing air gaps. This makes the soil more stable and increases its strength, load-bearing capacity, and resistance to water seepage. Compaction is important in construction because it prevents settlement, cracks, and uneven ground. If soil is not compacted properly before laying foundations, roads, or pavements, the structure may sink or break over time. Compaction is usually done using rollers, rammers, or vibrating machines. Well-compacted soil ensures a strong base for buildings and reduces future maintenance problems.

22. What is bearing capacity of soil?

The bearing capacity of soil is the maximum load or pressure the ground can safely carry without sinking or failing. It tells engineers how much weight can be placed on the soil before the foundation or structure becomes unstable. Soft soils have low bearing capacity, while rocky or compact soils have high capacity. It is measured in kN/m² (kilonewtons per square meter). Engineers use tests like Standard Penetration Test (SPT) or Plate Load Test to find this value. Knowing the bearing capacity helps in designing safe and stable foundations for buildings and other structures.

23. What is a shallow foundation?

A shallow foundation is a type of foundation that transfers building loads to the soil near the surface. It is placed at a depth less than or equal to its width. Shallow foundations are used when the topsoil is strong enough to support the structure. Common types include isolated footings, combined footings, and raft foundations. These are used in houses, small buildings, and light structures. They are easier and cheaper to build compared to deep foundations. Shallow foundations are suitable for areas with good soil conditions and lighter structural loads.

24. What is a deep foundation?

A deep foundation is used when the surface soil is too weak to support a structure. In this case, the load is transferred to deeper, stronger layers of soil or rock. Deep foundations go far below the ground, usually more than the width of the foundation itself. Common types include pile foundations, drilled shafts (caissons), and well foundations. These are used for high-rise buildings, bridges, towers, and other heavy structures. Deep foundations are more expensive and complex but provide better support in poor soil conditions or for heavy loads.

25. What is the difference between cohesion and friction in soil?

Cohesion and friction are two properties that help soil stay together and support loads:

- Cohesion is the force that holds soil particles together, especially in clay. It acts like a glue and gives the soil strength even without pressure.

- Friction is the resistance between soil particles when they slide over each other, mainly found in sandy or granular soils.

Cohesive soils stick together, while frictional soils hold firm due to particle interlock. Both properties affect how soil behaves under loads and are important in foundation design and slope stability.

26. What is settlement in soil?

Settlement is the downward movement of the ground when a load (like a building) is placed on it. It happens when soil particles get compressed or water is squeezed out from the soil. A little settlement is normal, but too much or uneven settlement can cause cracks and damage to buildings. There are three main types: immediate, consolidation, and differential settlement. Engineers try to reduce settlement by using proper foundations, compacting soil, or improving soil properties. Understanding soil behavior helps prevent structural problems and keeps buildings safe and stable.

27. What is a retaining wall?

A retaining wall is a structure built to hold back soil on a slope or elevated area. It prevents the soil from sliding or eroding, especially in hilly areas or near roads. Retaining walls are used to create level surfaces, protect buildings, and support roadways, gardens, basements, and cuttings. They can be made from concrete, stone, bricks, timber, or reinforced earth. The wall must resist the pressure from the soil behind it, which increases with height. Drainage is also important to reduce water pressure and prevent wall failure.

28. What is an SPT (Standard Penetration Test)?

The Standard Penetration Test (SPT) is a common method used to test soil strength and determine how compact or loose it is. It involves driving a split spoon sampler into the ground using a hammer and measuring how many blows are needed to go a certain depth (usually 30 cm). This number is called the SPT N-value. Higher values mean denser, stronger soil; lower values mean loose, weak soil. SPT is widely used for foundation design, especially for buildings, roads, and bridges, because it gives a quick idea of the soil’s bearing capacity.

29. What is the difference between clay and sand?

Clay and sand are both types of soil, but they are very different in properties:

- Clay has very fine particles, holds water, and sticks together. It has high plasticity and shrinks or swells with moisture.

- Sand has larger particles, drains water quickly, and doesn’t stick together. It is non-plastic and doesn’t change volume much.

Clay is cohesive and slow to drain, while sand is frictional and stable. These differences affect how each type is used in construction. For example, clay can be unstable under heavy loads, while sand is good for drainage layers.

30. Why is drainage important in foundation design?

Drainage helps remove excess water from around a building’s foundation. It is important because water can weaken the soil, reduce its strength, and cause settlement or foundation failure. Poor drainage leads to wet soil, which can expand (especially clay), push against walls, or cause erosion. In cold areas, water may freeze and damage the foundation. Engineers use systems like drain pipes, gravel layers, and sloped grading to keep water away from the structure. Good drainage keeps foundations dry, strong, and long-lasting, and it reduces the risk of cracks and structural damage.

Structural Engineering

31. What is a shear force and bending moment diagram?

A shear force and bending moment diagram shows how internal forces change along the length of a beam.

- Shear force is the force that tries to cut the beam across its length.

- Bending moment is the force that tries to bend the beam.

These diagrams help engineers understand where the beam experiences maximum force or bending.

By drawing these diagrams, we can design the beam safely and decide where reinforcement is needed. These tools are used in designing bridges, floors, and structural frames.

32. Define axial, bending, and torsional stress.

These are three types of stress in structural members:

- Axial stress: Happens when a force is applied along the length (axis) of a member — either pulling (tension) or pushing (compression).

- Bending stress: Created when a beam bends under a load. The top may compress, and the bottom may stretch.

- Torsional stress: Caused when a member is twisted, like in shafts or spiral staircases.

Each stress affects the strength and stability of a structure differently. Engineers check these stresses to make sure buildings and bridges can handle loads without breaking.

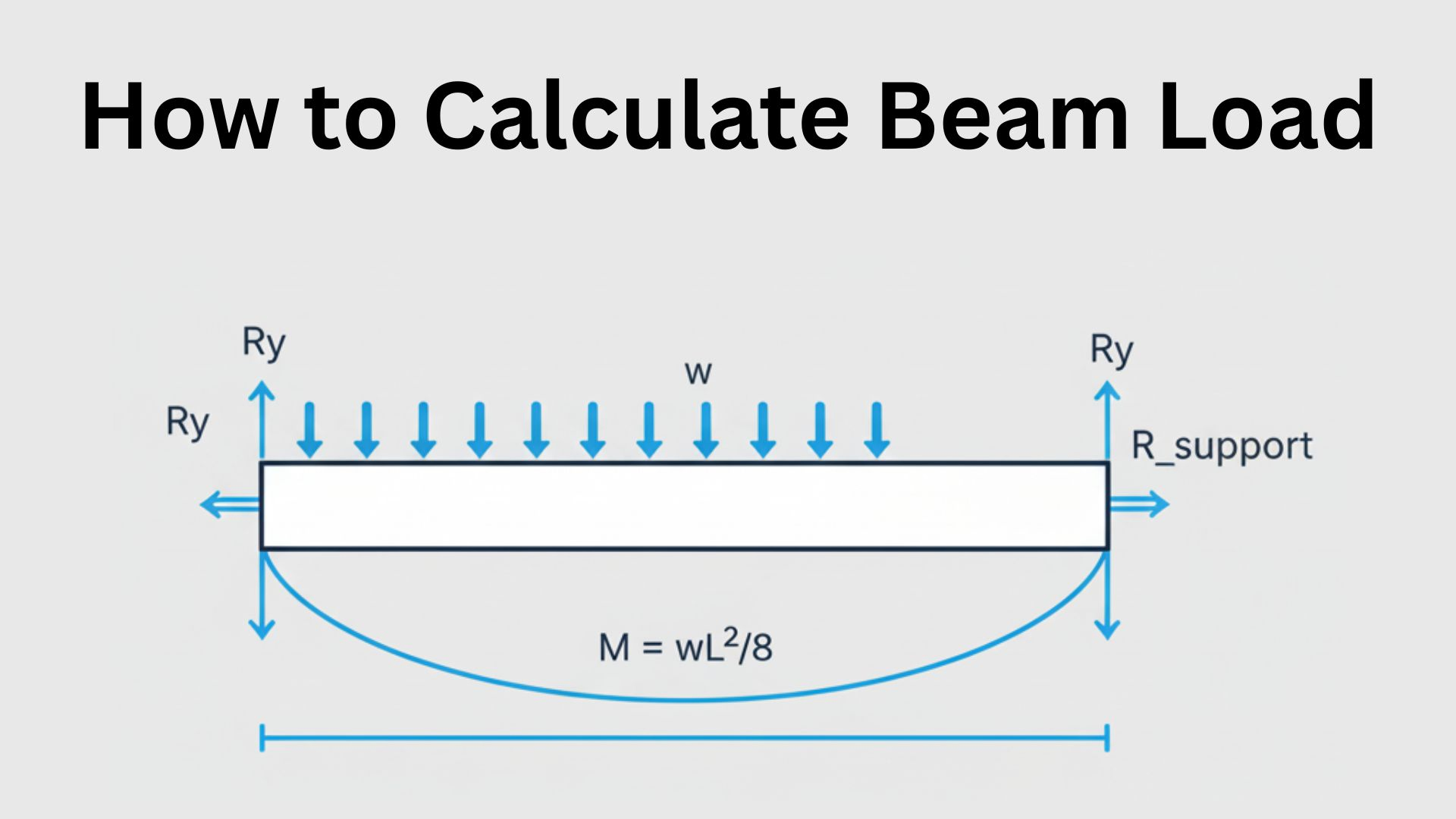

33. What is a simply supported beam?

A simply supported beam is a beam that rests on two supports — one at each end — and is free to rotate at the supports. It cannot resist moment at the ends but can carry vertical loads. This is the most basic and common beam used in construction.

Examples:

- A wooden plank placed over two bricks.

- Floor beams resting on walls.

Simply supported beams are easy to design and analyze. They are used in houses, bridges, and buildings where the beam spans between walls or columns.

34. What is the difference between one-way and two-way slab?

The difference depends on how the load is distributed:

- One-way slab: The slab is supported on two opposite sides. The load is carried in one direction. Used when the longer span is more than twice the shorter one.

- Two-way slab: Supported on all four sides. Load is shared in both directions. Used when the slab is nearly square.

One-way slabs are used in narrow rooms or corridors. Two-way slabs are used in square rooms or halls. The design method and steel reinforcement layout differ in both types.

35. What is prestressed concrete?

Prestressed concrete is concrete in which steel cables or tendons are tensioned (stretched) before or after pouring the concrete to improve its strength. This helps to reduce cracks and deflection.

There are two types:

- Pre-tensioning: Steel is stretched before concrete is poured.

- Post-tensioning: Steel is stretched after the concrete sets.

This method is used in bridges, parking structures, and long-span buildings, where normal concrete would crack under heavy loads. Prestressing makes concrete stronger, lighter, and more durable.

36. What is buckling in columns?

Buckling is a sudden sideways bending or collapse of a column when it is compressed. It doesn’t happen because the material is weak, but because of the slender shape and length of the column. Long, thin columns are more likely to buckle than short, thick ones.

It can occur even at loads lower than the column’s crushing strength. Buckling depends on column length, shape, material, and support conditions. Engineers calculate the critical load to prevent buckling and ensure the column stays stable.

37. What is Euler’s formula for column design?

Euler’s formula is used to find the critical load at which a slender, long column will buckle. It is: Pcr=π2EI(Leff)2P_{cr} = \frac{\pi^2 EI}{(L_{eff})^2}Pcr=(Leff)2π2EI

Where:

- PcrP_{cr}Pcr = critical buckling load

- EEE = modulus of elasticity of the material

- III = moment of inertia

- LeffL_{eff}Leff = effective length of the column

This formula is valid for long, slender columns under axial compression. It helps engineers design safe columns by ensuring the load is below the critical buckling value.

38. What are boundary conditions in structural analysis?

Boundary conditions define how a structure is supported or restrained at its ends. They tell us whether a structure can move, rotate, or is fixed in place. Common types:

- Fixed: No movement or rotation.

- Pinned: Can rotate but not move.

- Roller: Can move in one direction but not vertically.

Knowing the boundary conditions helps in calculating reactions, bending moments, and deflections correctly. They are essential in analyzing beams, frames, and trusses and ensuring the structure behaves as expected under load.

39. What is the importance of reinforcement in RCC?

RCC (Reinforced Cement Concrete) combines concrete with steel bars (reinforcement). Concrete is strong in compression but weak in tension. Steel is strong in tension.

Adding reinforcement:

- Increases concrete’s ability to resist bending, tension, and shear.

- Prevents cracks and structural failure.

- Helps in supporting heavy loads.

Steel bars are placed in areas of the structure where tension is expected (like the bottom of a beam). RCC is widely used in columns, beams, slabs, and foundations due to this combination of strength and flexibility.

40. What is the minimum cover required for slabs and beams?

Cover is the thickness of concrete provided above the reinforcement bars to protect them from moisture, fire, and corrosion.

Minimum cover values as per IS Code (general practice):

- Slabs: 15 mm to 20 mm

- Beams: 25 mm to 40 mm

Cover ensures the steel doesn’t rust and maintains the structure’s strength over time. It also helps the structure withstand fire for a certain period. The required cover depends on the type of structure, exposure to weather, and durability needs.

Highway & Transportation Engineering

41. What is the camber of a road?

Camber is the slight upward curve given to the surface of a road. It is higher in the middle and slopes down on both sides. The main purpose of camber is to drain rainwater off the road quickly so that water doesn’t collect and damage the road. The amount of camber depends on the type of road and climate. A typical camber may be 1 in 50 or 1 in 60. It helps keep the road dry, safe, and long-lasting by protecting the surface and preventing potholes or cracks caused by standing water.

42. What is the super-elevation in roads?

Super-elevation is the tilting of the road surface on curves. The outer edge of the road is raised higher than the inner edge. This helps vehicles overcome the centrifugal force when turning, reducing the risk of skidding or overturning. It makes turning safer at higher speeds. Super-elevation is commonly seen on highways and curved roads, like in hilly areas or at highway exits. The amount of super-elevation depends on the curve radius and vehicle speed, usually ranging from 4% to 10%. Engineers design it to ensure smooth and safe vehicle movement.

43. What is the ideal gradient for highways?

The gradient is the slope or steepness of a road. It is expressed as a ratio (e.g., 1 in 20) or percentage (e.g., 5%). On highways, gradients are provided to help vehicles move up or down with ease and safety.

- Ideal gradient: Gentle slope suitable for vehicles without reducing speed.

- In India, the ideal gradient is 1 in 30 to 1 in 40 (about 2.5% to 3.3%).

Too steep a slope can cause accidents or make it hard for vehicles to climb. Gradients must balance comfort, safety, and fuel efficiency.

44. Define CBR test and its purpose.

CBR (California Bearing Ratio) test is a soil strength test used to check how well the ground can support road layers. It measures the resistance of soil to penetration by a standard plunger. Higher the CBR value, the stronger the soil.

Purpose:

- To decide the thickness of road layers (subgrade, base, etc.).

- To check suitability of soil for road construction.

CBR test is simple and widely used in road projects. A typical highway may require a CBR value of 6% to 10% for the subgrade. It helps ensure a strong and durable road.

45. What are bituminous and rigid pavements?

There are two main types of road pavements:

- Bituminous pavement (Flexible pavement): Made of layers with bitumen (asphalt) on top. It is flexible and can bend slightly under traffic. Used for most roads and highways.

- Rigid pavement: Made of cement concrete. It is strong, durable, and does not bend. Used in airports, toll plazas, and heavy traffic areas.

Bituminous roads are cheaper and faster to build but need more maintenance. Rigid roads cost more but last longer and need less repair. The choice depends on traffic, cost, and climate.

46. What is Marshall Stability Test?

Marshall Stability Test is a lab test used to check the strength and flexibility of bituminous mix used in road construction. A small sample of the bitumen mix is made and tested under load to find:

- Stability: Maximum load it can handle.

- Flow: How much it deforms under load.

This test helps engineers decide the best mix of bitumen and aggregates for strong and long-lasting roads. It ensures the road will not crack, deform, or fail under traffic. The test is widely used in designing flexible pavements.

47. Define traffic volume and traffic density.

- Traffic volume: The number of vehicles passing a point on a road during a specific time (usually per hour or day). It helps in planning road width, signals, and lanes.

- Traffic density: The number of vehicles present on a road section at a given time, usually measured per kilometer.

In simple terms, volume is about movement, while density is about how crowded a road is. Both are important for traffic management, road design, and avoiding congestion.

48. What is the width of a standard lane in India?

In India, the standard lane width for roads is:

- Single lane: 3.75 meters

- Two-lane road: 7.0 meters total (3.5 m each lane)

- Urban roads: 3.5 meters or sometimes 3.0 meters depending on traffic

This width is designed to allow safe movement of cars, trucks, and buses. It also considers safety during overtaking and turning. The width may vary for rural, urban, or expressways based on vehicle type and traffic volume.

49. What are types of road pavements?

There are mainly three types of road pavements:

- Flexible Pavement: Made with bitumen (asphalt). Flexible, can bend slightly. Used in highways and city roads.

- Rigid Pavement: Made with concrete. Very strong, used in areas with heavy traffic or where long life is needed.

- Composite Pavement: A combination of both — concrete base and bitumen surface.

Each type is selected based on traffic, weather, soil condition, and budget. Flexible pavements are common, while rigid pavements are chosen for long-lasting roads like airport runways or bus terminals.

50. What are the components of a road cross-section?

A typical road cross-section includes:

- Carriageway: Main road surface where vehicles move.

- Shoulder: On both sides of the road for emergency parking or support.

- Side slope: Sloped edges for drainage and stability.

- Drain: To carry away rainwater.

- Footpath: For pedestrians (in urban areas).

- Median: Divider between lanes of opposite traffic.

- Subgrade: The soil layer below the road.

- Base course and sub-base: Layers that support the top layer.

These parts ensure safety, comfort, drainage, and durability of the road.

Surveying

51. What is surveying? Why is it important?

Surveying is the method of measuring distances, angles, and positions on the earth’s surface. It helps in mapping land, locating boundaries, and preparing plans for construction. Surveying is used before starting any construction work like roads, buildings, bridges, or dams.

It is important because:

- It provides accurate land measurements.

- Helps in designing layouts for buildings and roads.

- Ensures construction happens in the right place.

- It avoids land disputes by marking boundaries.

Without surveying, engineers and architects would not have the correct data to plan safe and effective projects.

52. What is the difference between plane and geodetic surveying?

- Plane surveying assumes the Earth is flat. It is used for small areas (like buildings or small land plots). Curvature of the Earth is ignored.

- Geodetic surveying considers the Earth’s curved surface. It is used for large areas, like mapping states or countries.

In plane surveying, simpler tools are used, and the calculations are easier. Geodetic surveying requires high-precision instruments and is used for long-distance or national surveys. Both are used depending on how big the land area is and the required accuracy.

53. What is a benchmark in leveling?

A benchmark is a fixed reference point with a known height (elevation). It is used during leveling to measure the height of other points on the land.

Types of benchmarks:

- GTS Benchmark: Fixed by government agencies.

- Arbitrary Benchmark: Chosen during a small project.

- Temporary Benchmark: Used only for a short time during a project.

Benchmarks help engineers ensure that all points are measured correctly and consistently, especially when constructing buildings, roads, or drains that need accurate levels.

54. Define chain surveying.

Chain surveying is the simplest type of land survey. It involves measuring distances using a chain or tape and making a rough sketch of the area. It is used for small, flat areas with few details.

Instruments used:

- Chain or tape

- Ranging rods

- Arrows

- Field book

Chain surveying is suitable for making property maps, plot layouts, and small civil works. No angles are measured, only straight-line distances between points. It is not suitable for hilly or uneven terrain.

55. What is a theodolite and how is it used?

A theodolite is an instrument used to measure horizontal and vertical angles with high accuracy. It is mounted on a tripod and rotated to take readings. It is used in:

- Surveying land

- Setting out buildings and roads

- Triangulation work

Theodolites are important for large construction projects and are used when precise angle measurement is needed. Engineers use it to ensure that roads, buildings, and bridges are aligned correctly.

Modern theodolites are often digital, making readings faster and easier to record.

56. What is total station?

A total station is a modern surveying instrument that combines:

- Theodolite (for angles)

- EDM (Electronic Distance Measurement) for measuring distances

- Computer and software for storing data

It can measure angles, distances, and elevations digitally and accurately. It also stores all the readings, which can be used to create maps or drawings.

Uses:

- Land surveys

- Road and building construction

- Mapping and layout

Total stations make surveying faster, more accurate, and efficient compared to manual methods.

57. What is GPS surveying?

GPS surveying uses satellites to determine the exact position (latitude, longitude, and height) of points on Earth. A GPS receiver receives signals from satellites and calculates coordinates.

It is used in:

- Land surveys

- Road alignments

- Mapping large areas

- Remote and difficult terrains

GPS is fast and useful when traditional surveying tools can’t be used. It works well in open areas, but not inside buildings or forests. It provides global coverage and helps in accurate planning and mapping.

58. What is the principle of levelling?

The basic principle of levelling is to find the height difference between two points using a horizontal line of sight. This is done by using a level instrument (like a dumpy level) and a staff.

The level is placed between two points, and readings are taken to find the difference in elevation. This helps in determining ground slopes and heights for construction.

Levelling ensures that:

- Roads and buildings are built at the correct levels.

- Drainage systems flow properly.

- Structures are stable and safe.

59.What are contour lines?

Contour lines are lines drawn on a map that connect points of the same elevation. They show the shape and height of the land.

- If contour lines are close together, it means a steep slope.

- If they are far apart, it shows a gentle slope.

- Closed contours may represent hills or depressions.

Contours help in understanding the terrain and planning:

- Roads and railways

- Dams and canals

- Buildings and drainages

They are very useful in hilly or uneven areas to avoid construction problems.

60. What are common errors in surveying?

Common surveying errors include:

- Instrumental errors – due to faulty tools (like misaligned levels or chains).

- Human errors – incorrect readings or recording mistakes.

- Natural errors – due to wind, temperature changes, or uneven ground.

Examples:

- Not leveling the instrument properly.

- Chain not being straight.

- Reading wrong staff values.

To avoid errors:

- Calibrate instruments regularly.

- Double-check measurements.

- Use proper methods and trained staff.

Minimizing errors ensures accurate maps, safe construction, and proper land usage.

Construction Management

61. What is CPM and PERT?

CPM (Critical Path Method) and PERT (Program Evaluation and Review Technique) are tools used in project planning and scheduling.

- CPM is used for projects with known time durations. It shows the critical path, which is the longest sequence of tasks that decides the total project time.

- PERT is used when task durations are uncertain or estimated, like in research projects.

Both help in:

- Planning the project timeline

- Managing resources

- Identifying important tasks

They are used in construction to finish work on time and avoid delays.

62. What is bar chart and Gantt chart?

A bar chart is a simple way to show project activities and their duration using horizontal bars. Each bar shows how long a task will take.

A Gantt chart is a type of bar chart that also shows the start and end dates, the sequence of tasks, and sometimes dependencies between tasks.

Both are used in construction to:

- Track project progress

- Schedule tasks

- Communicate plans with team members

They are useful for visual planning, especially in small and medium projects.

63. What is a project milestone?

A milestone is a key event or point in a construction project that shows important progress. It does not represent a task but marks the completion of a major phase.

Examples:

- Completion of foundation

- Approval of a design

- Delivery of equipment

Milestones help:

- Track project progress

- Identify delays

- Keep stakeholders informed

They act like checkpoints and are often used in reports and schedules. Meeting milestones on time helps ensure the entire project is moving as planned.

64. What is float in project management?

Float (or slack) is the amount of time a task in a project can be delayed without affecting the final project deadline.

Types:

- Total float: Delay allowed without delaying the project.

- Free float: Delay allowed without affecting the next task.

If a task is on the critical path, it has zero float, meaning it cannot be delayed.

Knowing float helps project managers:

- Plan resource allocation

- Adjust schedules

- Manage delays efficiently

It is a key part of CPM and helps keep the project on track.

65. What is the difference between direct and indirect costs?

- Direct costs are expenses directly related to the construction work.

Examples: labor wages, concrete, steel, equipment. - Indirect costs are overhead costs not tied to specific work items.

Examples: site office rent, electricity, supervision salaries.

In simple terms:

- Direct costs build the structure.

- Indirect costs support the construction process.

Understanding both helps in budget planning, cost control, and estimating project expenses correctly.

66. What are the stages of construction?

Construction usually follows these main stages:

- Planning and design – Drawings, approvals, budgeting

- Site preparation – Clearing land, setting up site office

- Foundation work – Excavation and laying base

- Structural work – Columns, beams, slabs

- Masonry and walls – Brick or block work

- Plumbing and electrical – Pipes, wiring

- Finishing – Plastering, painting, flooring

- Inspection and handover – Final checks and delivery

Each stage must follow quality and safety standards. Good project management ensures smooth flow between stages.

67. What is quality assurance vs quality control?

- Quality Assurance (QA) is the process to make sure the construction methods and materials will meet quality standards. It includes planning, training, and supervision.

- Quality Control (QC) is the checking and testing of materials and work during or after construction. It includes inspections, lab tests, and corrections.

In simple terms:

- QA = Prevent problems

- QC = Detect and fix problems

Both are important to ensure the building is safe, durable, and as per standards.

68. What is lean construction?

Lean construction is a modern method that focuses on reducing waste, improving efficiency, and increasing value for the client.

It follows the idea of “doing more with less.” This means:

- Better planning

- Less rework and delay

- Saving materials and time

It involves all team members (owners, engineers, workers) to work together. Tools like Last Planner System and Just-In-Time Delivery are used.

Lean construction helps deliver high-quality buildings faster and at lower cost, making it popular in large and complex projects.

69. What is scaffolding?

Scaffolding is a temporary structure made of pipes, planks, or metal frames, used by workers to reach higher areas during construction, painting, or repair.

Types of scaffolding:

- Tube and clamp

- H-frame

- Mobile scaffolding

- Suspended scaffolding

Scaffolding must be:

- Stable

- Well-supported

- Safe to climb

It ensures workers can move and work safely at heights. Safety gear like guardrails, helmets, and harnesses are often used with scaffolds.

70. What safety measures are followed on site?

Common safety measures on a construction site include:

- Personal Protective Equipment (PPE): Helmets, gloves, boots, safety vests

- Training: Workers are trained on how to handle tools and emergencies

- Barricading danger zones

- Proper scaffolding and ladders

- Fire safety equipment

- Regular safety checks

- Clear signage and instructions

Following these measures reduces accidents, protects workers, and ensures compliance with safety laws. A safe site leads to faster and smoother construction.

Hydraulics & Environmental Engineering

71. What is Bernoulli’s equation?

Bernoulli’s equation explains how energy in a flowing fluid (like water or air) is conserved. It states that the total energy – made up of pressure energy, kinetic energy (due to speed), and potential energy (due to height) – remains constant in a flowing fluid without friction.

In simple terms:

If the speed of a fluid increases, its pressure decreases, and vice versa.

It is used in:

- Designing pipes

- Aircraft wings (lift)

- Water supply systems

It helps engineers understand how fluids behave in motion and where pressure changes might happen.

72. What is Reynolds number?

Reynolds number is a number used to predict the type of fluid flow – whether it is laminar (smooth) or turbulent ( rough and chaotic).

It is calculated using the fluid’s speed, density, viscosity, and pipe size.

- Low Reynolds number (<2000) = Laminar flow

- High Reynolds number (>4000) = Turbulent flow

- Between 2000–4000 = Transition zone

Knowing Reynolds number helps in designing pipelines and channels because it affects pressure loss, energy use, and flow behavior.

73. What is the difference between laminar and turbulent flow?

- Laminar flow: Smooth and orderly flow where fluid moves in parallel layers. Found in slow-flowing water or narrow tubes.

- Turbulent flow: Chaotic and swirling flow where water moves in different directions. Seen in rivers, fast-moving water, and large pipes.

In laminar flow:

- Less energy loss

- Predictable behavior

In turbulent flow:

- More mixing of particles

- Higher energy loss

Engineers must consider the flow type when designing pipelines and water systems to reduce friction and energy loss.

74. What is head loss in pipes?

Head loss means the loss of pressure or energy in a pipe as water flows through it. This happens due to:

- Friction between the water and pipe walls

- Bends, fittings, valves, and other obstacles

Head loss is important because it affects:

- Water pressure at the outlet

- Pump size needed

- Overall system efficiency

To reduce head loss:

- Use smoother pipes

- Minimize bends

- Keep pipe length short

Engineers calculate head loss using formulas like Darcy-Weisbach and Hazen-Williams equations.

75. What are different types of flow in open channels?

In open channels like rivers, canals, and drains, water flows with a free surface (open to air). Types of flow include:

- Steady flow: Flow rate stays the same over time

- Unsteady flow: Flow rate changes with time

- Uniform flow: Depth and speed stay the same along the channel

- Non-uniform flow: Depth or speed changes along the channel

- Laminar or Turbulent flow: Based on fluid motion

Understanding flow types helps in designing channels for drainage, irrigation, and flood control.

76. What is sewage treatment?

Sewage treatment is the process of cleaning wastewater (from homes, toilets, factories) so it can be safely released into rivers or reused.

Steps in sewage treatment:

- Primary treatment: Removes large solids and particles

- Secondary treatment: Uses bacteria to break down organic matter

- Tertiary treatment: Removes chemicals, nutrients, and disinfects water

Proper treatment protects public health, reduces pollution, and helps in water conservation. Treated sewage can be used for gardening, industry, or even groundwater recharge.

77. Define BOD and COD.

- BOD (Biochemical Oxygen Demand): The amount of oxygen needed by bacteria to break down organic matter in water.

High BOD = more pollution. - COD (Chemical Oxygen Demand): The amount of oxygen needed to break down both organic and inorganic matter using chemicals.

COD is usually higher than BOD.

Both are important tests for measuring water pollution levels in sewage or industrial waste. Lower BOD and COD values mean cleaner water.

78. What is the difference between aerobic and anaerobic digestion?

- Aerobic digestion: Bacteria break down waste in the presence of oxygen. It’s faster and used in many sewage plants.

Example: Activated sludge process. - Anaerobic digestion: Bacteria break down waste without oxygen. It’s slower but produces biogas (methane) as energy.

Used for sludge and solid waste treatment.

Both processes reduce waste volume and make it safer to dispose or reuse. Anaerobic digestion is useful in biogas production and rural areas.

79. What are types of water treatment processes?

Water treatment involves steps to make raw water safe for drinking or use. Common processes include:

- Screening – Removes large particles

- Coagulation & Flocculation – Combines small particles

- Sedimentation – Allows heavy particles to settle

- Filtration – Removes fine particles

- Disinfection – Kills harmful bacteria (using chlorine, UV, or ozone)

Advanced methods:

- Reverse osmosis (RO)

- Activated carbon filtration

- Desalination

These ensure the water is clean, safe, and free from pollutants.

80. What is the function of sedimentation tank?

A sedimentation tank is used in water and sewage treatment plants to remove suspended solids by letting them settle at the bottom. The tank slows down water flow so that heavier particles settle, forming a sludge layer.

There are two main types:

- Rectangular

- Circular

The clean water flows out from the top, while sludge is removed from the bottom.

Sedimentation is an important step because it reduces the load on filters, saves energy, and improves the overall treatment process.

Estimation, Costing & Quantity Surveying

81. What is the thumb rule for steel in RCC?

The thumb rule is a quick way to estimate the quantity of steel in RCC (Reinforced Cement Concrete) structures. It is not exact but helps in early planning.

Common thumb rules:

- Slab: 80–100 kg of steel per cubic meter of concrete

- Beam: 100–130 kg/m³

- Column: 120–160 kg/m³

- Footing: 50–80 kg/m³

These values vary with design and load. Always confirm with a structural drawing. The thumb rule helps estimate cost and material needs before detailed calculations.

82. What is the unit of measurement for brickwork?

Brickwork is generally measured in cubic meters (m³) because it involves length × width × height of the wall.

- For example, a wall of 3m length, 0.2m thickness, and 2.5m height = 1.5 m³.

In some countries, smaller works (like half-brick walls) may be measured in square meters (m²).

The unit includes:

- Bricks

- Mortar

- Joints

Quantity surveying uses this unit to estimate materials and labor required for construction.

83. What is the deduction in plastering for doors and windows?

While calculating plastering area, we deduct the surface of:

- Doors

- Windows

- Large openings

Standard deductions (as per IS 1200):

- Up to 0.5 m² opening: No deduction

- Between 0.5 m² to 3 m²: Full deduction for one side only

- Above 3 m²: Full deduction for both sides

This means for small windows, we don’t subtract area. For large ones, we subtract both sides. This rule helps in accurate estimation of plaster material and labor.

84. What is bar bending schedule (BBS)?

Bar Bending Schedule (BBS) is a detailed list of all reinforcement bars used in an RCC structure. It includes:

- Bar diameter

- Shape

- Length

- Number of bars

- Cutting length

- Bend details

BBS is used to:

- Calculate total steel quantity

- Plan bar cutting and bending

- Avoid wastage

- Assist in billing and ordering

BBS is prepared from structural drawings and is crucial for site execution and steel management.

85. What are the components of a detailed estimate?

A detailed estimate includes the total cost of a project, broken into smaller parts. Components include:

- Material cost – Cement, steel, bricks, etc.

- Labor cost – Masons, helpers, operators

- Machinery charges – Mixers, cranes, etc.

- Transportation cost – Delivery of materials

- Contingency – Extra 3–5% for unexpected needs

- Overhead charges – Office, management, electricity

- Profit margin – Contractor’s profit

Detailed estimates help plan budgets, arrange funds, and compare contractor bids.

86. How do you calculate the quantity of cement, sand, and aggregate?

To calculate materials for concrete (like M20 grade), use this step-by-step method:

- Assume mix ratio: M20 = 1:1.5:3 (cement : sand : aggregate)

- Total parts = 1 + 1.5 + 3 = 5.5

- For 1 m³ concrete:

- Cement = (1/5.5) × 1.54 = 0.28 m³ = 8 bags

- Sand = (1.5/5.5) × 1.54 = 0.42 m³

- Aggregate = (3/5.5) × 1.54 = 0.84 m³

1.54 m³ is used as a dry volume factor.

This method helps estimate materials for ordering and costing.

87. What is rate analysis?

Rate analysis is the calculation of the unit cost (e.g., per m³ or m²) of a construction activity. It includes:

- Material cost

- Labor cost

- Equipment cost

- Overhead

- Contractor’s profit

Example: To find the rate of 1 m³ brickwork, we calculate:

- Number of bricks

- Cement and sand needed for mortar

- Labor wages

- Add overhead and profit

Rate analysis helps in:

- Estimating project cost

- Preparing tenders

- Budget planning

88. What is a bill of quantities (BOQ)?

Bill of Quantities (BOQ) is a document that lists all items of work in a project along with their quantities and units.

Each item includes:

- Description of work

- Unit (e.g., m², m³)

- Quantity

- Rate

- Total cost

BOQ helps:

- Contractors to quote properly

- Engineers to control costs

- Owners to understand project cost

It is used in tenders, contracts, and billing.

89. What is overhead cost in a project?

Overhead cost refers to the indirect expenses of running a construction project. These are not directly tied to building a wall or column but still necessary.

Examples:

- Site office rent

- Project manager salary

- Electricity and water

- Transportation

- Supervision

Overheads are usually 5–15% of the project cost. They are added to direct costs to find the total project cost.

Understanding overheads helps in better budgeting and cost control.

90. How is excavation measured?

Excavation is usually measured in cubic meters (m³) because it involves volume.

Formula:

Length × Width × Depth = Volume in m³

Excavation types:

- Earthwork in foundation

- Trenches for pipelines

- Pits for columns or tanks

Measurements are taken before and after excavation to check the removed soil volume. In sloped or stepped pits, average dimensions are used. Accurate measurement helps in billing and planning backfilling and disposal.

General HR & Behavioral Questions

91. Tell me about yourself.

I’m a civil engineering graduate with strong interest in structures and construction. I completed my degree from [Your College] and did academic projects on concrete mix design and building planning. I enjoy solving practical problems, working in teams, and learning on-site. I’m also comfortable with AutoCAD and MS Excel. I’m hardworking, punctual, and always ready to learn. My goal is to start my career in a good company where I can apply my knowledge, gain experience, and grow professionally. I believe civil engineering is a field that helps shape the world, and I’m excited to be a part of it.

92. Why did you choose civil engineering?

I chose civil engineering because I’ve always been interested in buildings, roads, and how cities are built. I enjoy subjects like math and physics, and civil engineering gave me a way to apply those in real life. I wanted to be part of the process that creates safe homes, strong bridges, and better infrastructure. It’s a field where you can physically see your work and help society grow. Also, civil engineering offers many options like construction, design, environment, and transportation, which makes it an exciting and meaningful career choice for me.

93. What are your strengths and weaknesses?

Strengths:

I’m sincere, dedicated, and a quick learner. I adapt well to new environments and enjoy solving real-world problems. I also have good teamwork and communication skills.

Weaknesses:

Sometimes, I try to do everything on my own and hesitate to ask for help, but I’m working on improving that by learning how to delegate and collaborate better. I also want to improve my public speaking and confidence in group settings.

I’m always open to feedback and try to turn weaknesses into learning opportunities.

94. Describe a project you worked on during your academics.

In my final year, I worked on a project titled “Design of a G+2 Residential Building.” We designed the entire structure using AutoCAD and analyzed load distribution. We calculated steel and concrete quantities, designed footings, slabs, and beams, and prepared a cost estimate. We also studied green building practices to include sustainable design. I was responsible for bar bending schedule and structural drawings. This project helped me understand practical aspects of design, teamwork, and time management. It was a great experience where I applied classroom knowledge to a real-world scenario.

95. How do you handle stress on-site?

I handle stress on-site by staying calm and focusing on the solution, not the problem. I make a checklist of tasks, set priorities, and take one step at a time. Communication also helps – I discuss issues with my team and seniors instead of trying to manage everything alone. I also ensure I get enough rest and stay hydrated, as physical health affects mental clarity. I understand that site work can be unpredictable, but staying focused, managing time, and staying positive helps me deal with challenges better.

96. Are you willing to relocate or work in remote areas?

Yes, I’m open to relocating or working in remote areas. I understand that as a civil engineer, many projects happen in different locations and may require working away from home. I see this as a chance to learn more, gain practical experience, and grow professionally. I am young and flexible, and I see relocation as a part of my job and learning process. As long as there is a good work environment and learning opportunity, I am ready to take it.

97. Where do you see yourself in 5 years?

In five years, I see myself as a confident and skilled civil engineer with strong on-site and technical experience. I want to take on more responsibilities, work on larger projects, and maybe lead a team. I plan to improve my knowledge by doing certifications or a master’s degree in a specialized field like structures or project management. I want to contribute to a company’s success while building a solid career path for myself. I also aim to stay updated with new technologies and continue learning every day.

98. Why should we hire you?

You should hire me because I’m a hardworking and enthusiastic fresher who is eager to learn and grow. I may not have job experience yet, but I have strong fundamentals in civil engineering, a positive attitude, and willingness to put in the effort required. I’m sincere, responsible, and ready to take challenges. I believe I’ll bring fresh energy, learn quickly, and adapt well to your work culture. I’m looking forward to starting my career with a company like yours and contributing to your ongoing projects.

99. Do you prefer office work or site work?

I’m open to both, but I prefer site work initially because it gives practical experience and helps understand real challenges. Being on-site helps me apply what I’ve studied, observe construction methods, and learn from engineers and supervisors directly. Later, I would like to gain some office-based experience too, like planning, estimation, and design, so I can understand both sides of the job. Overall, I want to be flexible and learn from every opportunity, whether it’s on-site or in an office.

100. Have you faced any failure? How did you handle it?

Yes, during college, I once failed in my first attempt at a structural design assignment. I felt disappointed, but instead of giving up, I took feedback from my teacher and reworked the calculations. I also studied from extra sources and practiced more. In the second attempt, I not only passed but scored well. This taught me that failure is part of learning, and with effort and support, I can overcome challenges. Since then, I’ve seen failure as a step toward improvement, not the end.

101. Do you have any questions for us?

Yes, thank you. I’d like to know:

- What kind of training or mentorship is offered to freshers?

- Can you tell me about the team I would be working with?

- What are the growth opportunities for freshers in your company?

I’m excited about this opportunity and eager to contribute and learn.

✅ Final Tips for Interview Preparation

Understand the Basics: Revise your engineering subjects, especially concrete technology, soil mechanics, and structures.

Keep Updated: Know about current technologies like BIM, green buildings, and new construction materials.

Practical Knowledge: Be familiar with tools, drawings, and common site practices.

Soft Skills Matter: Communicate clearly, maintain eye contact, and show enthusiasm.

Conclusion

Getting ready for a civil engineering interview as a fresher can be a bit scary, but with the right preparation, you can do really well. Focus on understanding the basic concepts and be ready to explain them in simple words. Practice common questions and try to give real-life examples. Be honest, stay calm, and show that you are eager to learn. Interviewers want to see your interest and positive attitude, not just your knowledge. Keep learning, stay confident, and believe in yourself. With good preparation, you can give a great interview and start your journey as a civil engineer.